System Upgrade Substantially Increases Efficiency of Major Tissue Manufacturer

Since going online, Major Tissue Manufacturer’s new ECS-enhanced system has re-established interest from operators as an OEE improvement tool and enabled dramatic improvements to the facility’s efficiency.

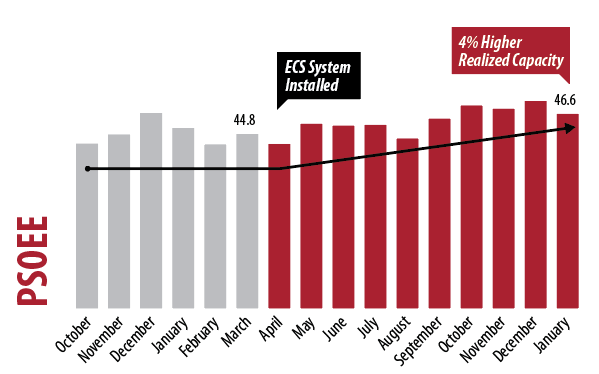

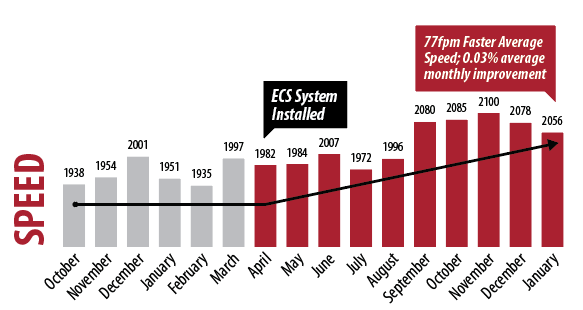

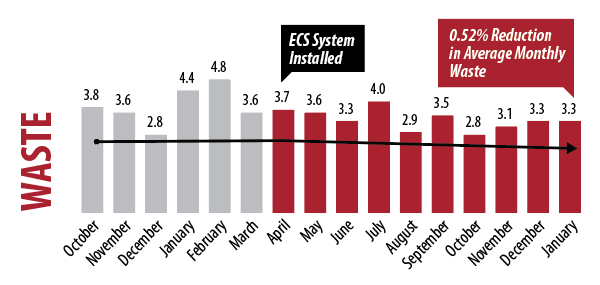

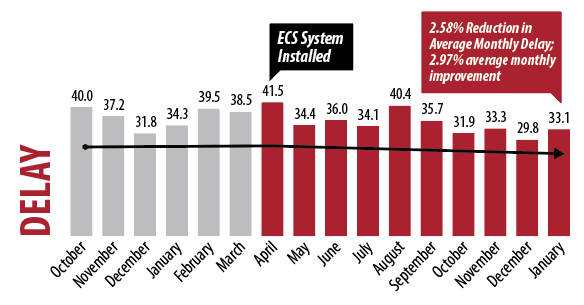

The average rate of PSOEE (Product System Overall Equipment Efficiency) improvement in the 6 months prior to the upgrade was only 0.29% month-over-month. In the 9 months since the upgrade was completed, average PSOEE is over 4% higher, with a PSOEE improvement rate jumping to 3.83% month over month. Efficiency gains have also been measured in regards to Speed, Waste, and Delay.

“Having the ECS camera system added to our lines has enabled operations to troubleshoot daily issues, decreased downtime on our lines, and enabled us to run to our production goals.”

- Ben Brisco, Electrical Engineer

Challenges

Major Tissue Manufacturer’s Facility had camera systems installed on their Bath-1 and Bath-2 converting lines since inception, but the system went largely unused by operators due to the software being difficult to use and out of date.

With much of the original camera system hardware still functioning, they sought an upgrade that integrated new functionality and ease of use with the existing installation instead of investing in a costly new system with a lengthy install.

ECS Solutions

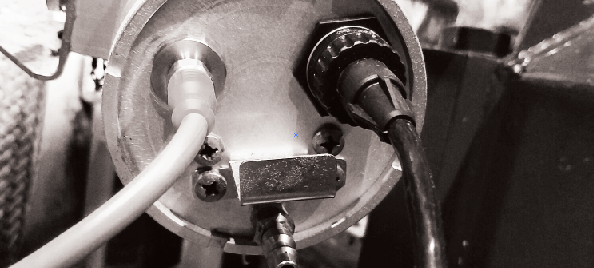

To get the best possible performance out of the facility’s existing cameras, 51” constant-on strip LED modules were installed strategically to optimize capture without creating problematic shadows or interfere with operator access to machinery. The cameras were encased in ECS timed air-cleaning enclosures to keep equipment safe and operator interaction minimal. Installing a 23” touchscreen panel-mount monitor allowed operators to interface with cameras intuitively and quickly to target crucial data, even when wearing gloves.

In addition to cameras, the system utilized the previous installation's cabinet and backbone to keep costs low. To prevent the system from falling out of use like the previous one, ECS provided hands-on training to give operators solid working knowledge of the system and lower the barrier of comfort related to use. The software was configured with a simple user interface to ensure regular operator utilization.

All critical ECS functions can be done by Touchscreens actions. A system that is easy to navigate will get used more by operators. This means more problem-solving and increased machine efficiency.

The upgraded system was configured using the existing rack and backbone of the previous installation.

Closeup of the custom ECS camera enclosure with timed air cleaning functionality.